7360 DDC – TUBE INDEPENDENT CONTROLLER

HARDWARE:

- All the existing 7355x pcb’s have been combined onto a single board that handles the all functionality of the old controller.

- The important part of this is it no longer lakes an experienced technician to troubleshoot furnace problems. Regardless of the type of problem, the tech simply swaps out the existing controller pcb with a replacement and returns the questionable board to us for testing and repair. This will reduce tool downtime on the tool to minutes as opposed to hours or possible days.

- Also since all functionality is contained on a single board, subsequent down time will eliminated in the case of a tech replacing the wrong pcb and the issue reoccurring.

- Another single board benefit is that the SETUP & local recipe storage is contained on the separate interface pcb so the user should never have to reprogram the setup data when the controller pcb is replaced. It should just be a matter of swapping out the pcb and powering the controller back up and the tool should be back in production.

- The old CRT has been replaced by a color LCD flat panel. The new display does not suffer from the limitations of the old crt such as screen burn in, fading displays and jittery screen caused by AC noise present in the fab.

- The hardware is both supportable and sustainable removing the existing problem of obsolesce due to individual components no longer being available (7355x was designed in mid 70’s).

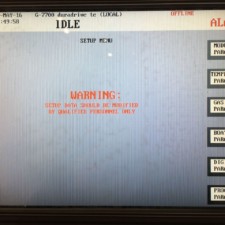

- Easily retrofitable, unit is plug and play (after one time setup data entry).

- The enclosure is dimensionally compatible with mounting area of existing 7355.

- All cable interconnects are the same or conversion interconnects are included in the retrofit kit.

- Installation consists of removing the old 7355X and attaching the existing BIC bus, I/O bus and Apex cables and the unit is ready to power.

- Controller is backwards compatable with older BTI modules (temperature, gas and boat) so User can keep his existing module hardware.

FIRMWARE:

- The majority of the firmware was been ported from our existing APOGEE vertical process controller which has had years of production time in various manufacturing plants. This is important because the firmware has a proven track record for performance and reliability.

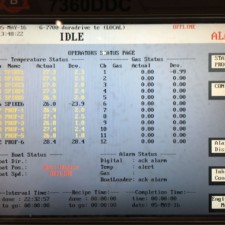

- The user interface has been keep as close as possible to the existing 7355X interface to reduce the need to retrain operators on the operation of the tool. There are some obvious changes that have evolved over a period of time to improve and add functionality to the controller.

- All firmware is contained in flash memory, no mechanical drives that are prone to failure.

- The controller is designed to appear as a standard 7355X to the Apex control system. This means there are no issues when sharing processes between existing 7355X’s and the new controller. This is beneficial because it means the customer can replace units at their own pace, there are no limitation on running a combined fab of both 7355 and 7360s.

EXTENDED CAPIBILITIES:

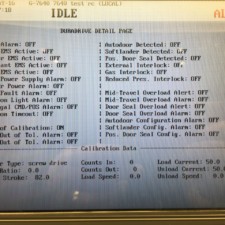

- All controller and remote module (Intempos and Duradrive) setup data is programmable from the 7360 front panel. This means the customer no longer need to attach a diag term when replacing a remote module. Whenever the 7630 senses a module has just come on line, all the setup data is sent from the controller to the module, therefore assuring any replaced module will be operating with the same parameters as the unit it replaced.

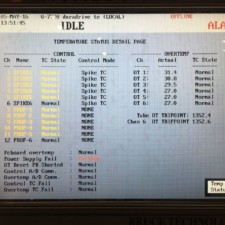

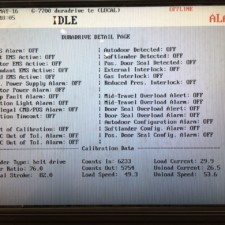

- Extended status monitoring of remote modules ( Intempos and Duradrive). All of the additional hardware status available only on the diag term is now displayed at the 7360 front panel. This will provide the operator / tech with all the additional information necessary to monitor / troubleshoot the furnace.

- Extended communication diagnostics. All of the BIC bus, I/O bus and Apex serial communications are monitored for communication errors and logged to the controller and displayed on the diagnostic status page.

- Additional control on interval redirect (the user can force a redirect so the controller will not default to ramping the temperature back to setpoint on an interval redirect.

- Immediate abort recovery support where the user can recover from an aborted process with a single press, returning then to the source interval with the durations adjusted for time already spent in the interval before the abort.

New Screens: